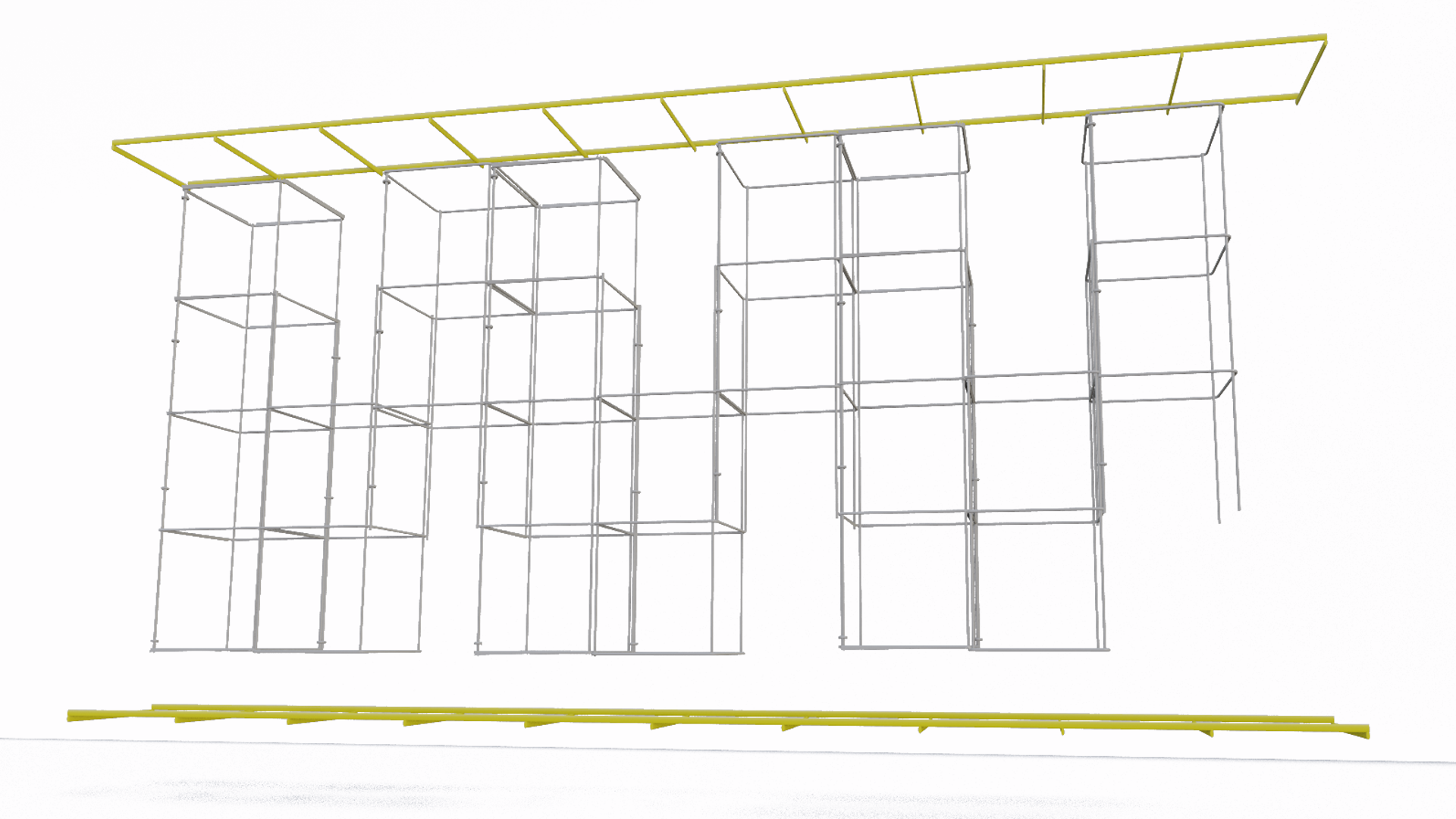

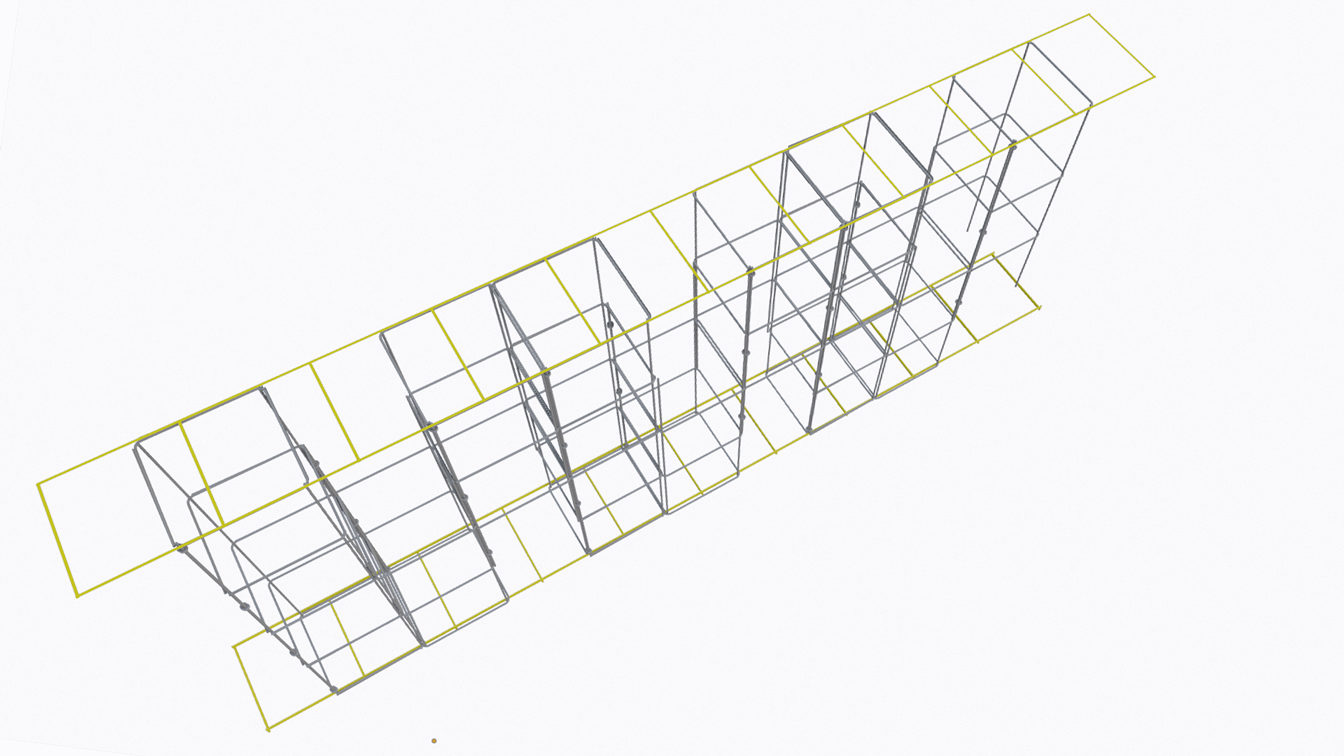

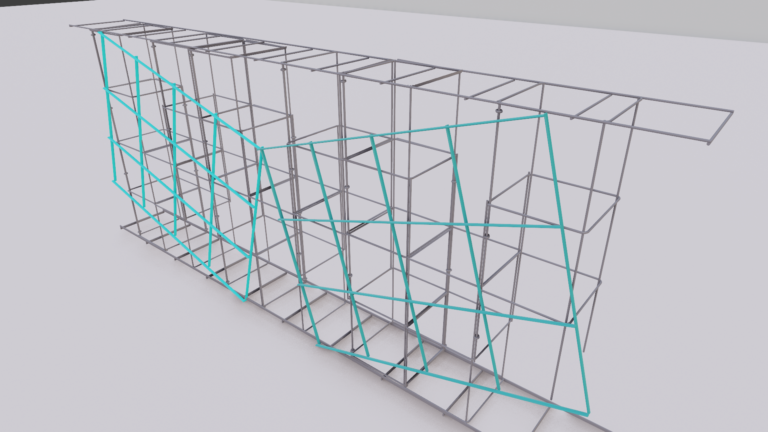

The building blocks for the Flex-Shell Framing Process

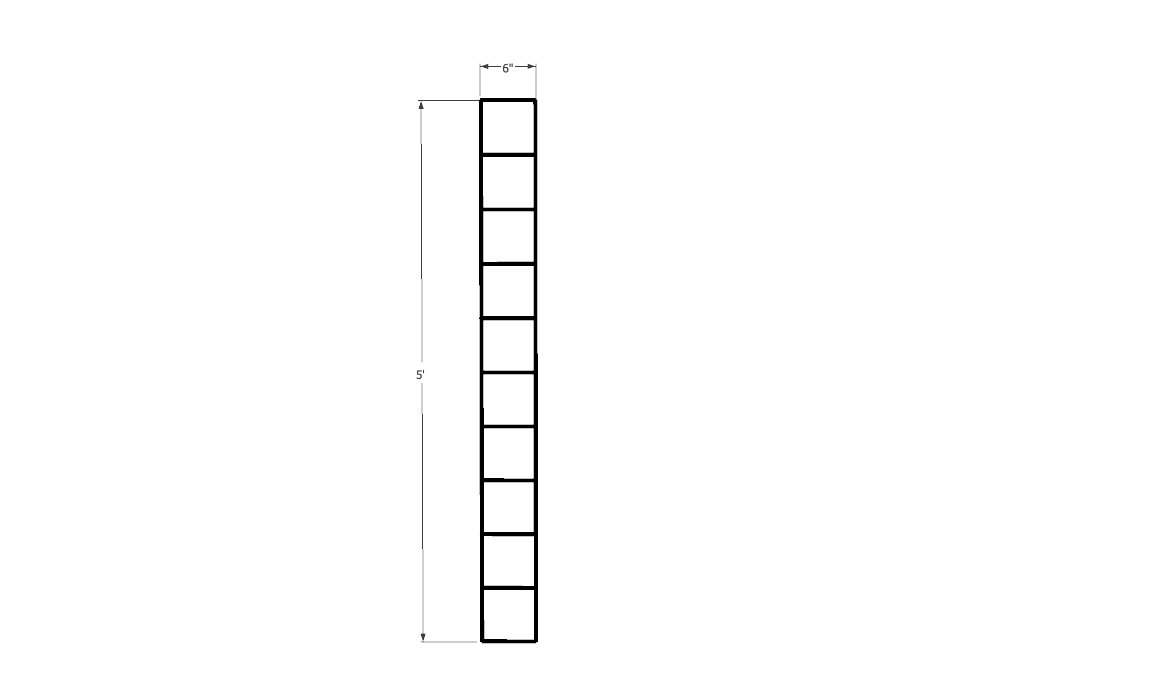

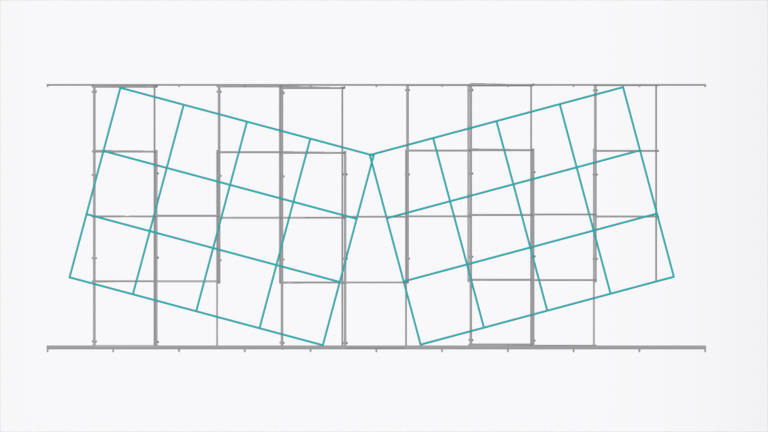

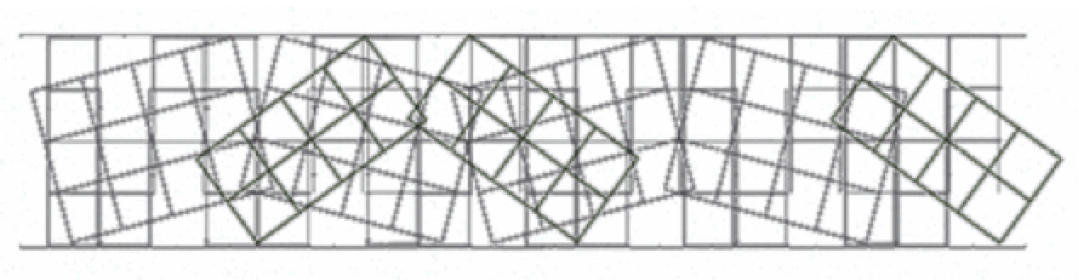

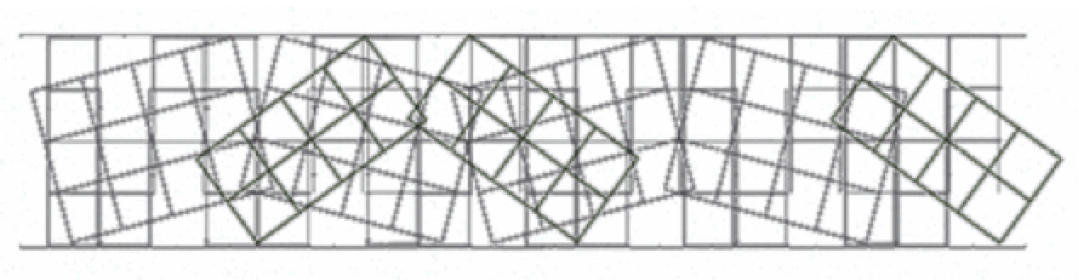

The Ribbon is a 1×10 flat strip of steel that is placed on the top and bottom of the trusses to create truss chords, that define a structural performance of a truss, and overlap enough so they cannot slip. The truss chords lock the bottom line and top line of a truss into a rigid ribbon that the internal reinforcing attaches to. The Ribbon is also very important for smoothly blending shapes. This process reveals the beauty of exploring and expressing organic form while controlling it precisely so the most stable form is economically discovered, like in nature.

When two forms are blended, such as a column base to nearby overhead arch, a ribbon is used to establish a single smooth arching connection that follows a needed design parameter, such as a curve for proper head clearance. Other ribbons are then attached to that curve and connected to other parts of the connection form so the complex curvilinear shape that connects the two forms with optimum flex-stable geometry stability, is revealed, which is key to exploring and defining accurate bio-metric form of optimum structural performance.

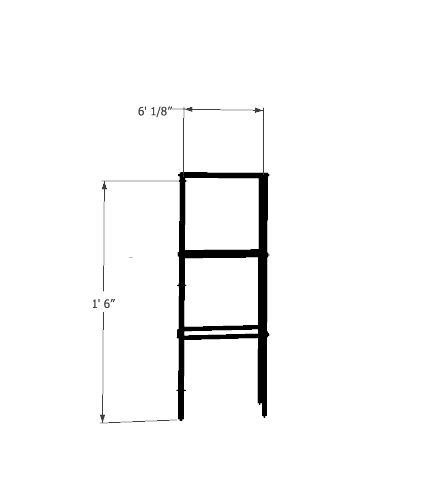

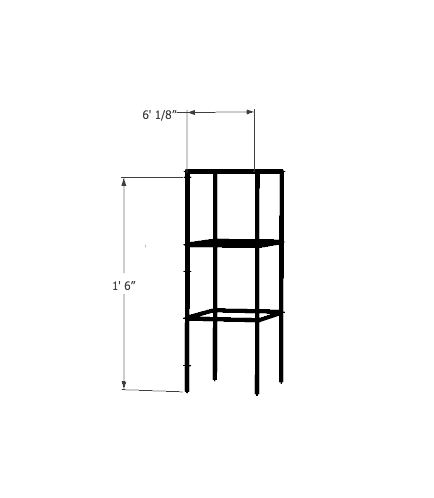

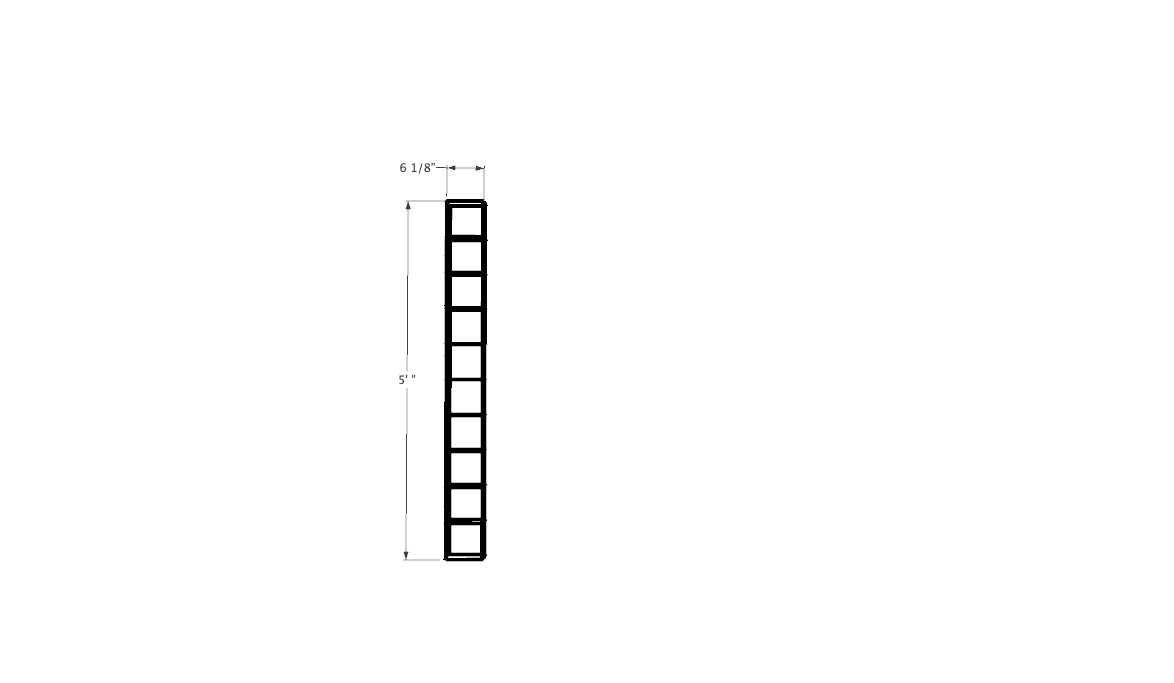

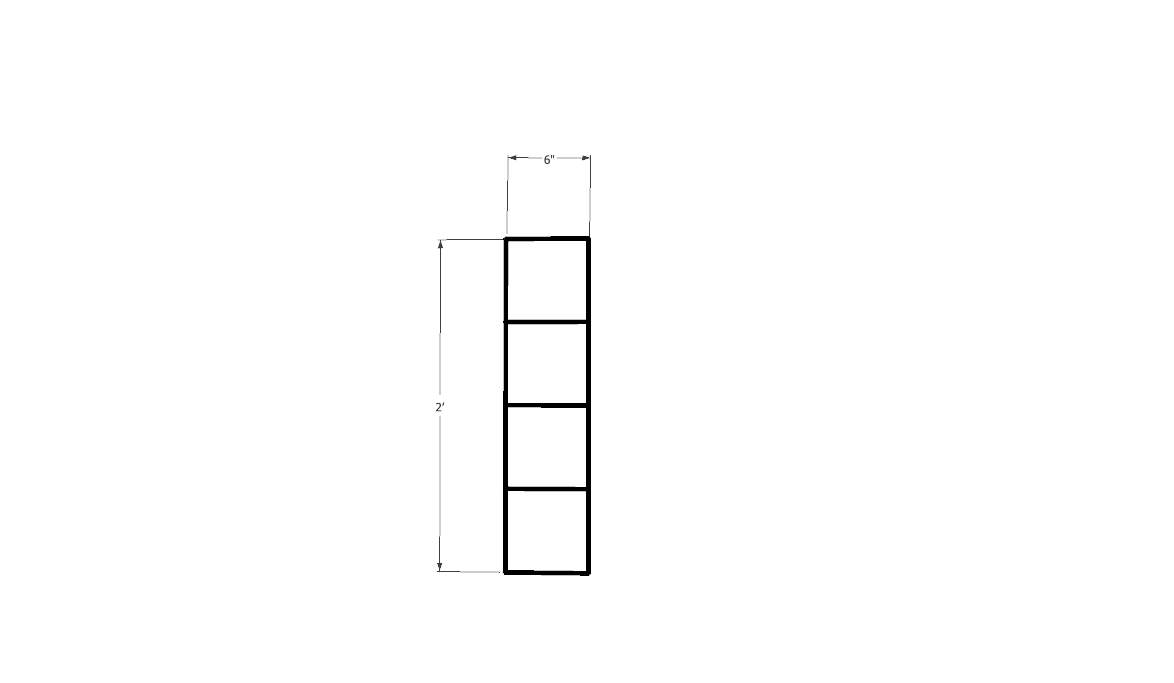

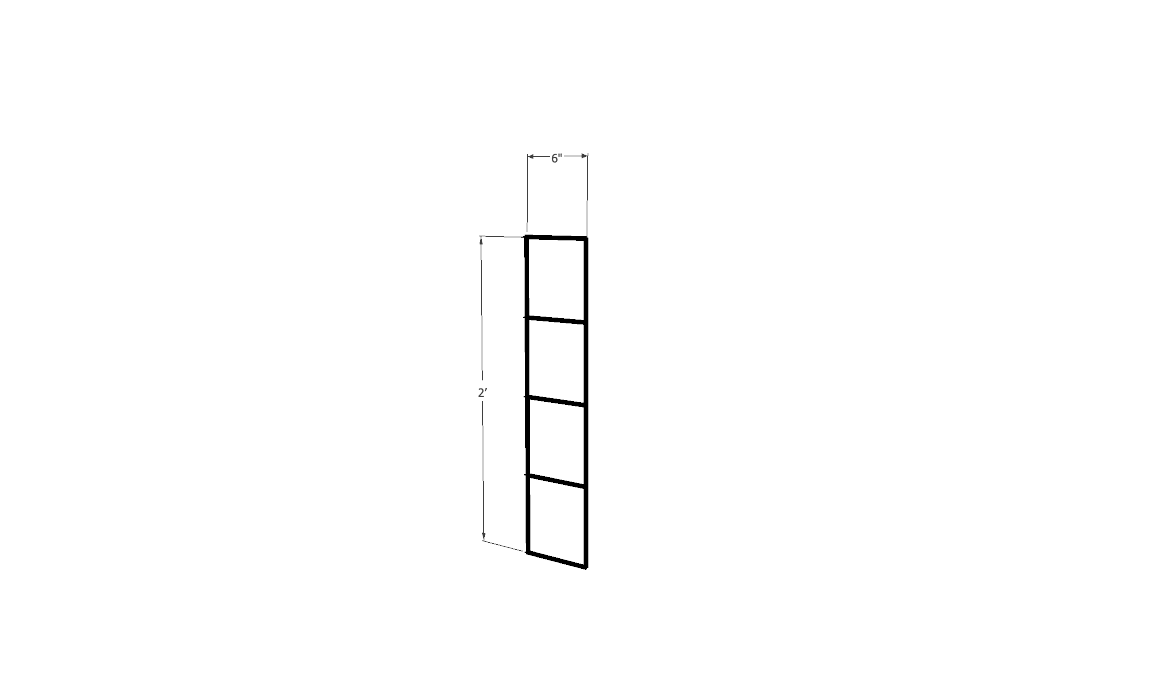

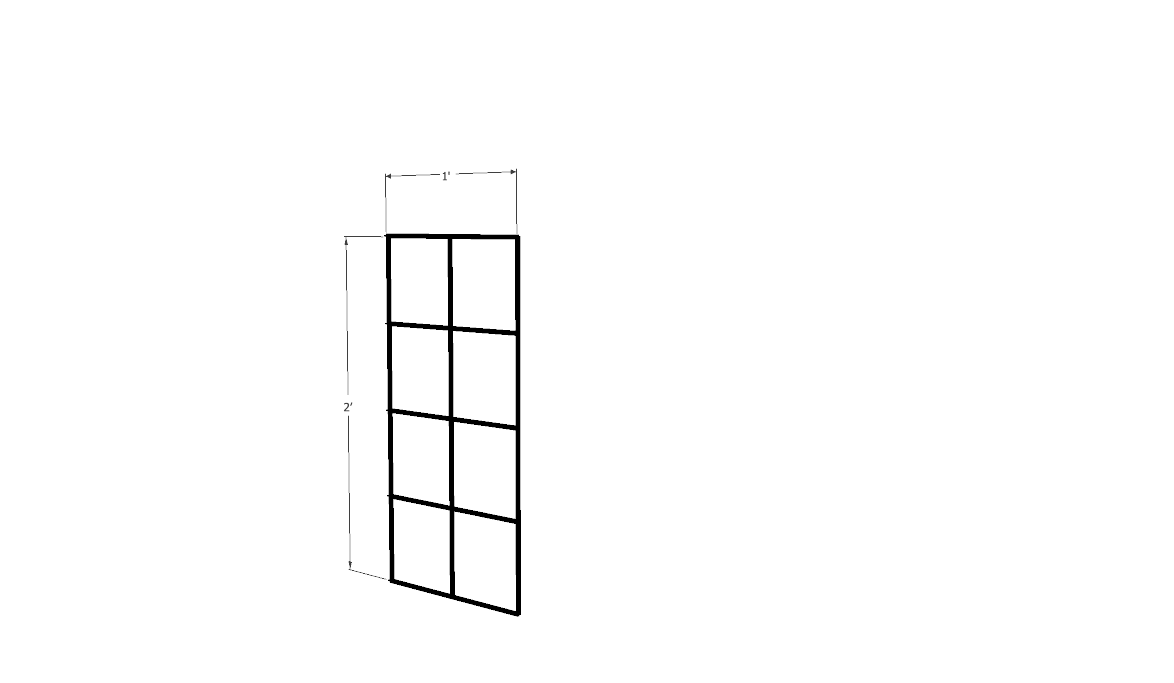

1x5 Reinforcing Ribbon

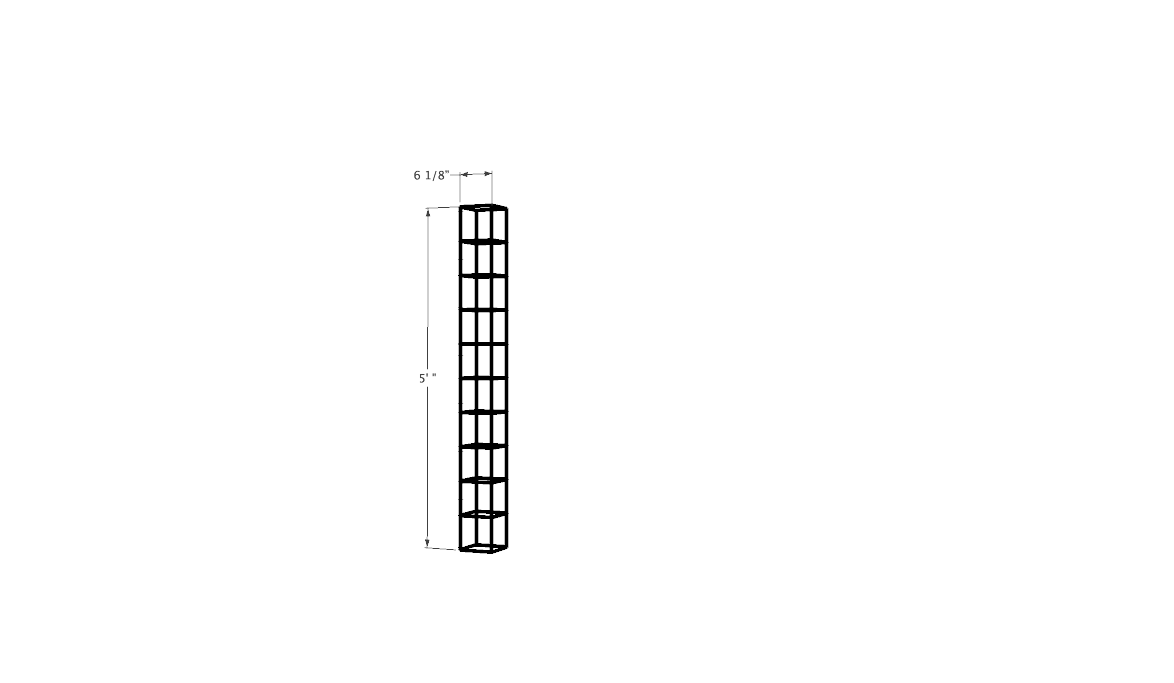

3 x 4 side truss reinforcing pieces are placed in a crisscross pattern that is attached corner to corner (one corner on the top ribbon chord and one corner on the bottom ribbon chord), which helps to lock the chord into position so it is sturdy and cannot deflect under a load.

.

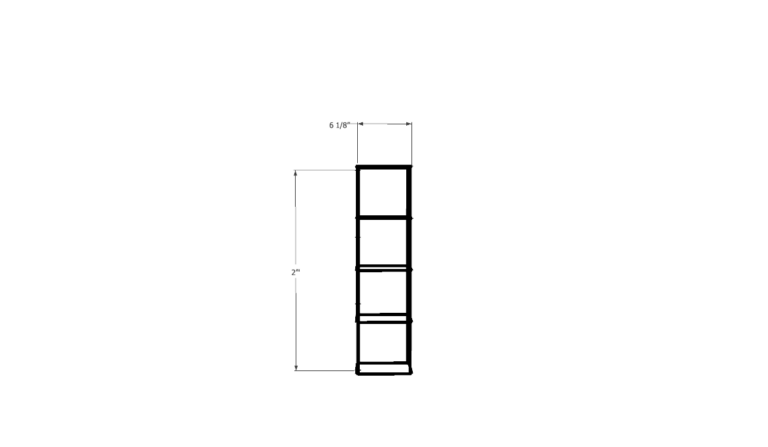

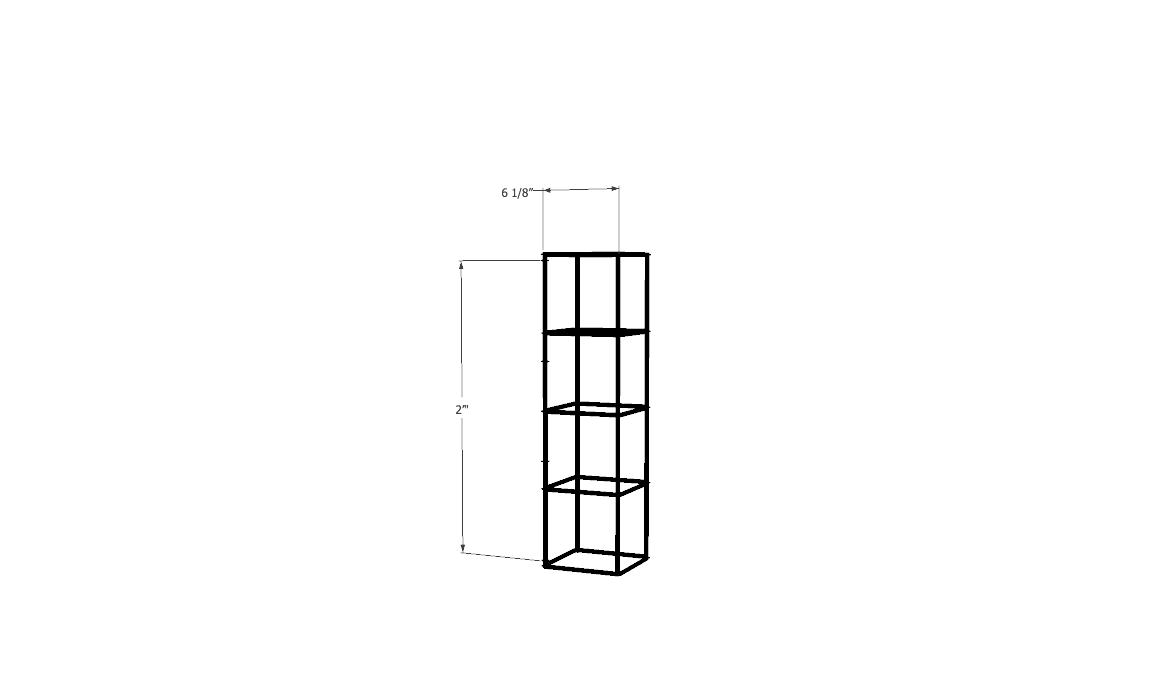

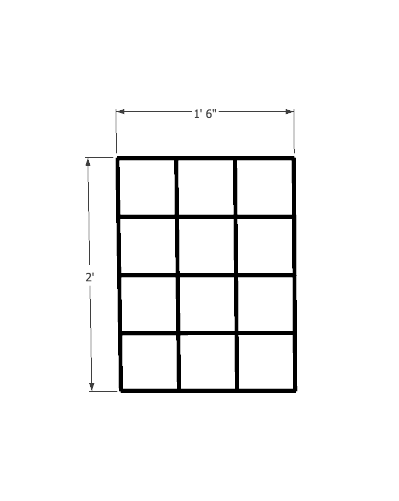

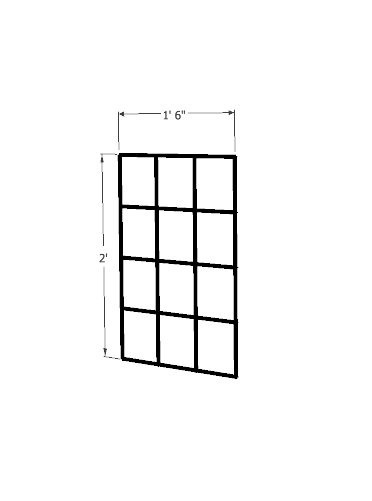

2 Cube Blocks are used to make a truss